Cov ntaub ntawv khoom

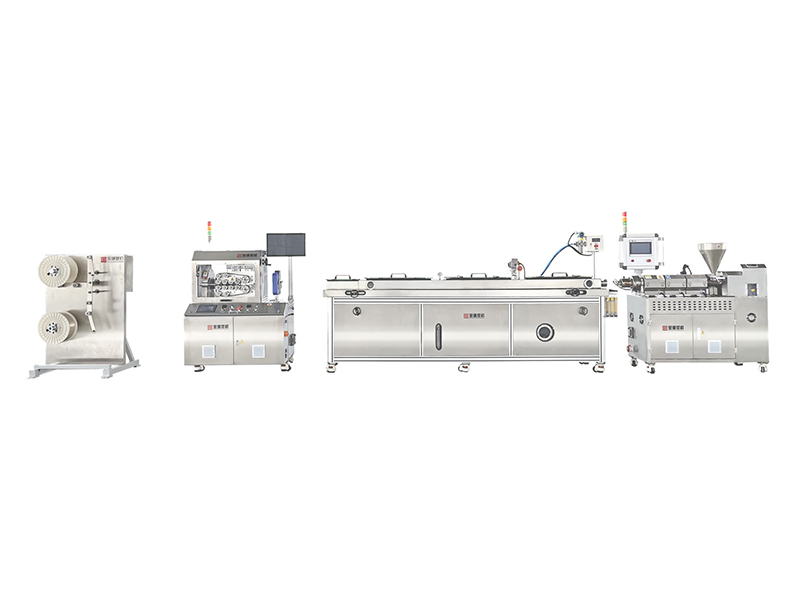

Piv nrog rau cov yas yas thiab engineering yas, fluorine plastics muaj ntau yam zoo heev thiab ntau yam ntawm lub cev, xws li nyob rau hauv ntau qhov kub thiab txias, nws muaj qhov tshwj xeeb hardness, hnav tsis kam, tsis kam rau tshuaj lom neeg thiab kub kub. Nyob rau hauv daim ntawv thov yuav tsum tas li txhim kho kev kho mob, kev lag luam tsheb, kev lag luam kev sib txuas lus thiab lwm yam, fluorine yas yeeb nkab muaj ntau thiab ntau daim ntawv thov.

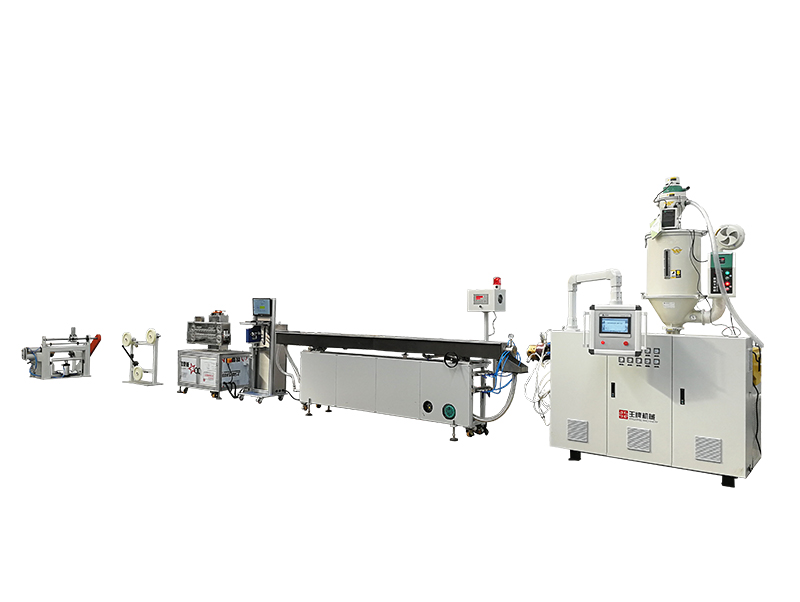

Rau fluorine yas extrusion molding, KINGSWEL Machinery BAODIE tuam txhab muaj ntau xyoo kev tshawb fawb, kev loj hlob thiab debugging tshwm sim, tshwj xeeb tshaj yog nyob rau hauv kev kho mob fluorine yas conduit thiab multilayer composite tsheb tubing khoom, muaj peev xwm muab mature thiab ruaj khov ua tiav cov txheej txheem extrusion, debug txheej txheem kev taw qhia, thiab ntau yam kev pabcuam turnkey.

Pebqhov zoo

Fluorine Yas Yeeb Nkab Extrusion Kab Nta

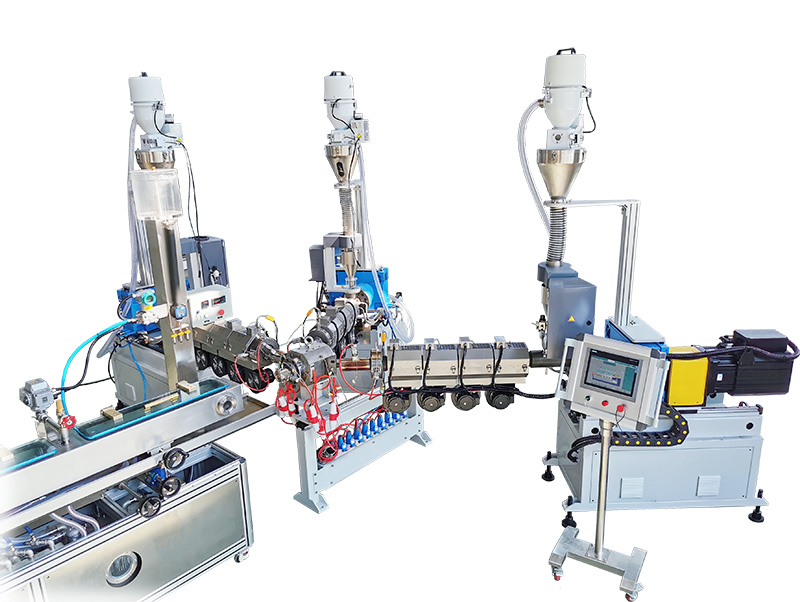

- Lub thoob thiab ntsia hlau ntawm extruder txais yuav tshiab #3 pwm steel khoom, nrog zoo corrosion kuj thiab kub resistant, muaj peev xwm ua tau raws li fluorine yas extrusion plasticizing ua.

- Cov cua kub ntawm lub thoob yog ua los ntawm tooj liab lossis cam khwb cia hlau rhaub, tuaj yeem ua tau raws li qhov ruaj khov ntawm kev ua haujlwm siab tshaj 500 ℃.

- Cov tuag tau txais kev siv tshuab CNC siab heev thiab electrochemical machining txoj kev rau kev ua tiav, ua tau raws li txoj kab uas hla ≤1.0mm catheter zoo tagnrho txoj kev;

- Cov khoom siv pwm kuj yog cov tshiab # 3 pwm hlau, nrog kev ua haujlwm zoo corrosion thiab kub resistant kev ua tau zoo;

- Kev siv lub tswv yim tshiab "lub tshuab nqus tsev tsis muaj zog" thev naus laus zis: lub tshuab nqus tsev thiab cov dej sib cais tswj, los ntawm ntau theem dej sib npaug tswj qhov system thiab lub tshuab nqus tsev sib koom ua ke kom ntseeg tau tias cov txheej txheem tsim khoom yog lub tshuab nqus tsev ruaj khov, cov dej txias txias du thiab ntws ruaj khov.

- Kev tswj lub tshuab nqus tsev siv txoj kev meej dua, tuaj yeem ua tiav kev tswj qhov tseeb ntawm -0.01KPa qib;

- Cov khoom siv fluorine sib txawv muaj qhov sib txawv ntawm kev ua haujlwm kub, yaj viscosity, liquidity thiab thiaj li nyob rau, qhov sib piv calibration txhais tau tias kuj muaj ntau yam: nqus qhuav calibration, nqus immersion da dej calibration, sab hauv siab calibration thiab lwm yam sib txawv.